- In Line

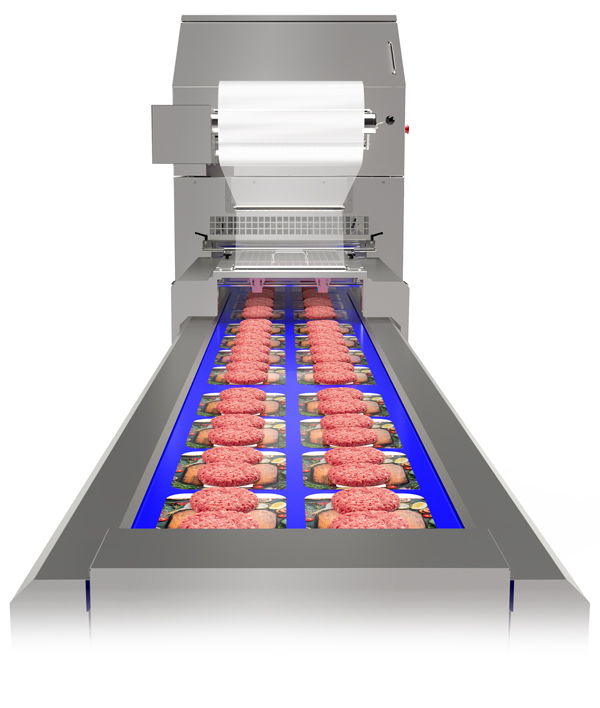

FoodPack FastBoard

FoodPack FastBoard is the new ILPRA FoodPack revolutionary model. It allows flat board containing the product to be moved by simply placing them on a belt, without the need for jaws. The sealing mould, unlike the moulds used on the market, doesn’t need a lower part that moves upwards, but the sealing operation is done only through the upper bell that closes directly on the belt. The possibility of adjusting the starting height of the bell, depending on the product to be packaged, makes it possible to obtain the highest possible speed by optimising the closing phase.

This ILPRA model completely revolutionises the skin packaging concept of the conventional in-line traysealers on the market. High productivity, flexibility of use and cost reduction are the major strengths of this new technology, which respects ILPRA’s philosophy of uncompromising packaging quality.

| Technical Data | FoodPack FastBoard | ||

| Dimensions | 597 x 97 x h 204 cm | ||

| Weight | circa 1900 Kg | ||

| Air Consumption | 6 bar – 80 Nlt/cycle | ||

| Sealing Area | 1130 x 400 x protrusion height 70 mm |

Sealing directly on the belt

Unlike in-line traysealers on the market, the sealing of the flat bases takes place directly on the belt: this is a revolution in the concept of skin packaging.

Adjustable mould height

The mould of the FastBoard can be easily adjusted by PLC in such a way that the mould’s movement on the belt is minimised. This adjustment ensures process optimisation with a considerable increase in production speed.

Large sealing area

The large sealing area of the FastBoard allows eight 180 x 250 mm flat boards to be sealed simultaneously. The number of boards can be increased for smaller formats.

Maximum speed

Thanks to the large sealing area, the possibility to adjust the height of the mould and the direct sealing on the belt, an output of 50 pcs/min packed in skins can be achieved, which corresponds to a cycle rate of about 6.5 cycles/min

TECHNOLOGIES

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| ID CONTROL SYSTEM Recognition of authorised personnel by badge. Up to three levels of identification. |

| PREDICTIVE Predictive maintenance system that enables the planning of the overhaul and replacement of components. |

| EXTRASKIN SYSTEM It allows Skin packaging even at high degrees of protrusion. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |