- In Line

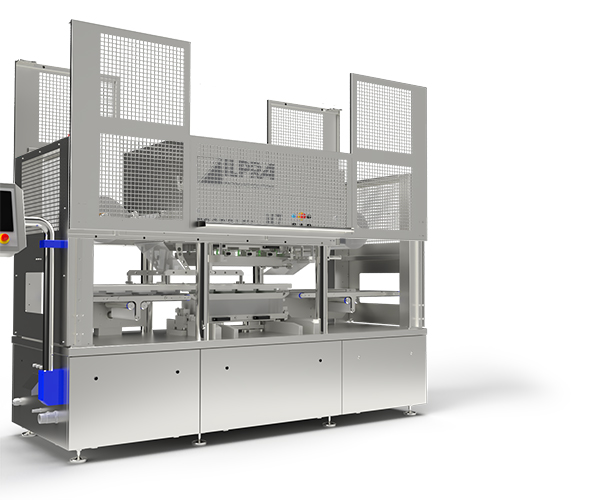

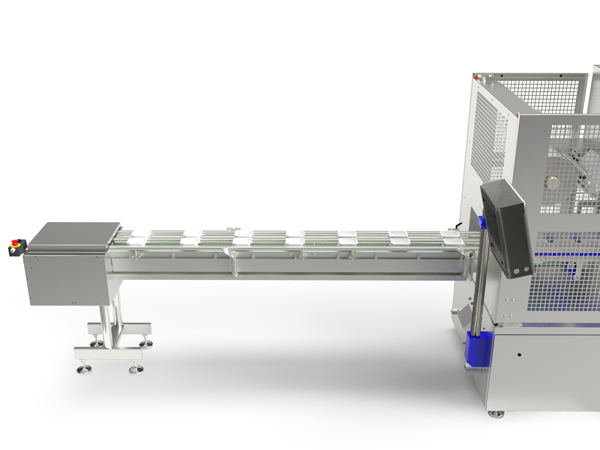

FoodPack M7

The M7 is a fully mechanical model that guarantees high performance and is designed to be easily accessible in all its components to facilitate cleaning operations. This allows greater ease of use, as well as guaranteeing effective sanitisation throughout the entire machine. Easy disassembly and short mould changeover, which can be carried out without additional tools. Standard on this model is the CPS technology that allows a constant inflow of trays, as well as the possibility of numerous customisations such as ID Control System, Anti-crush System and pre-heating system in the case of Skin packaging.

-

Sealing

Sealing

-

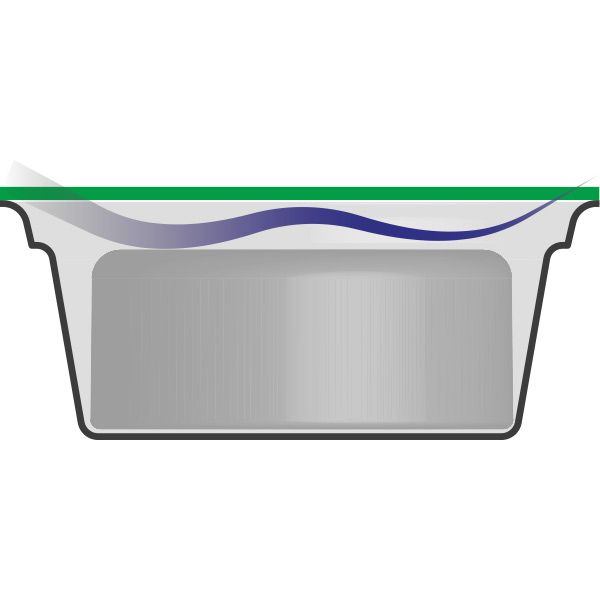

Gas Flush

Gas Flush

-

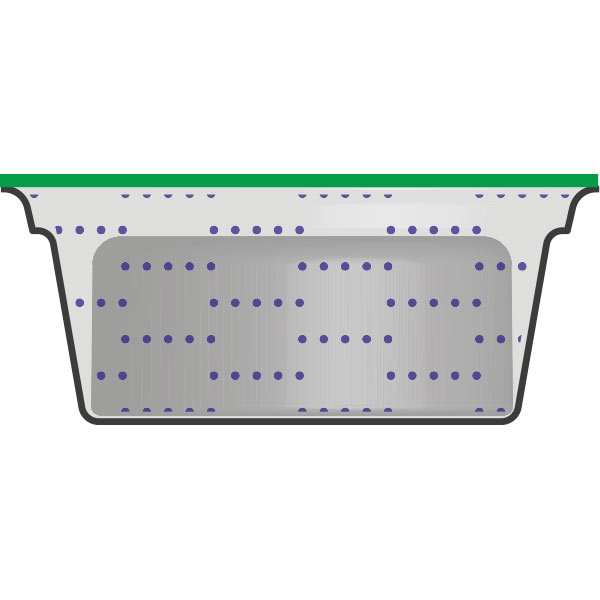

MAP/ATP

MAP/ATP

-

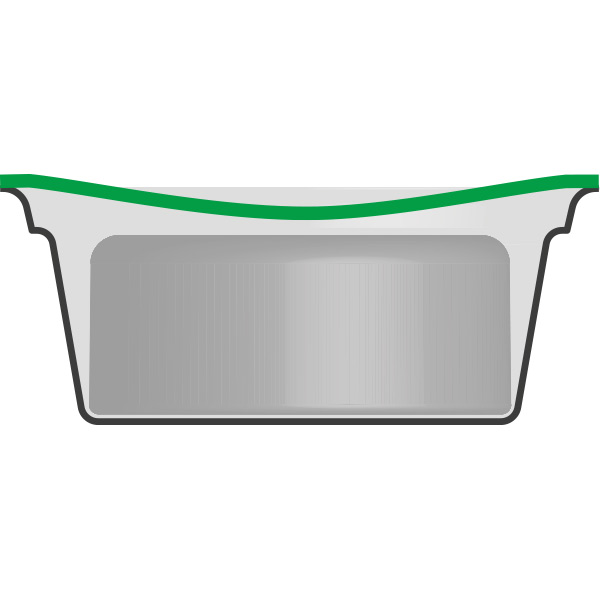

Vacuum

Vacuum

-

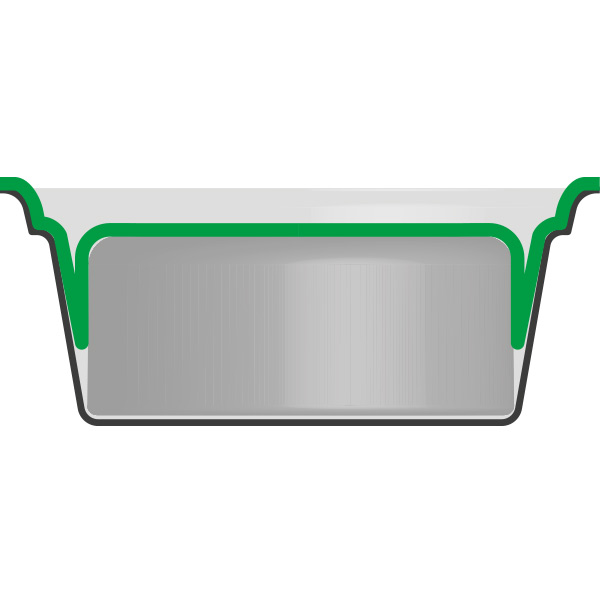

Skin

Skin

-

Overskin

Overskin

-

Extraskin

Extraskin

-

Extraskin on Cardboard

Extraskin on Cardboard

| Technical Data | FoodPack M7 | ||

| Dimensions | 377 x 134 x h 202 cm | ||

| Weight | circa 2500 Kg | ||

| Air Consumption | 6 bar - 6 Nlt/cycle | ||

| Sealing Area | 720 x 420 x h 120 mm |

CPS technology

Technology that allows a continuous inflow of trays into the machine. The conveyor belt automatically separates the trays that are transported, without ever stopping, into the sealing mould. To do this, the jaws are electronically interpolated with the conveyor belts.

Total accessibility

Protections are reduced to just 2 guards, front and rear, opening upwards to facilitate cleaning operations. This allows greater ease of use, as well as guaranteeing effective hygienisation of the entire machine.

OPTIONAL: double line feed

To achieve a higher output, this model can be equipped with a double line tray feed system.

Fully mechanical sealing

More precise and of higher quality than non-mechanical sealing.

TECHNOLOGIES

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. Available on all models in this line. |

| CONSTANT PLACEMENT SYSTEM Cutting-edge technology that enables a constant inflow of trays. The interpolation of the belts and jaws increases the production speed. |

| Optional: EXTRASKIN SYSTEM It allows Skin packaging even at high degrees of protrusion. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |

| Optional: ID CONTROL SYSTEM Recognition of authorised personnel by badge. Up to three levels of identification. |

| Optional: PREDICTIVE Predictive maintenance system that enables the planning of the overhaul and replacement of components. |

| Optional: ANTI-CRUSH SYSTEM The machine checks the correct positioning of the trays, stopping sealing in the event of incorrect positioning |