- Automatics

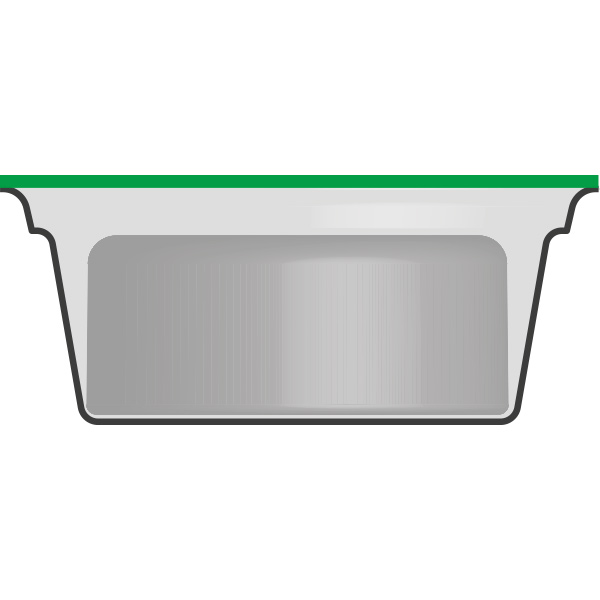

FoodPack Speedy +

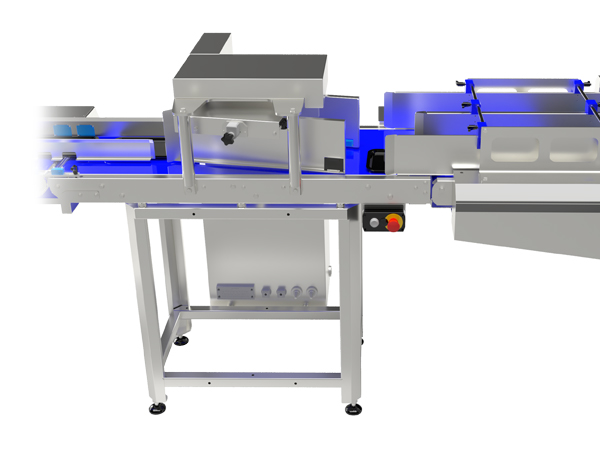

From the desire to make our popular FoodPack Speedy an in-line traysealer, comes Speedy +. This new model is capable of integrating into any production line, further increasing its already remarkable performance. The aim of our R&D department was to create an automatic packaging machine capable of working in-line with the aid of a double chain transport system. Speedy + achieves higher performance than the FoodPack Speedy PN20 model from which it derives, without neglecting precision during the transport of the containers.

Speedy + proves to be an excellent option for those who want to access a more automated solution while maintaining a limited budget.

-

Sealing

Sealing

-

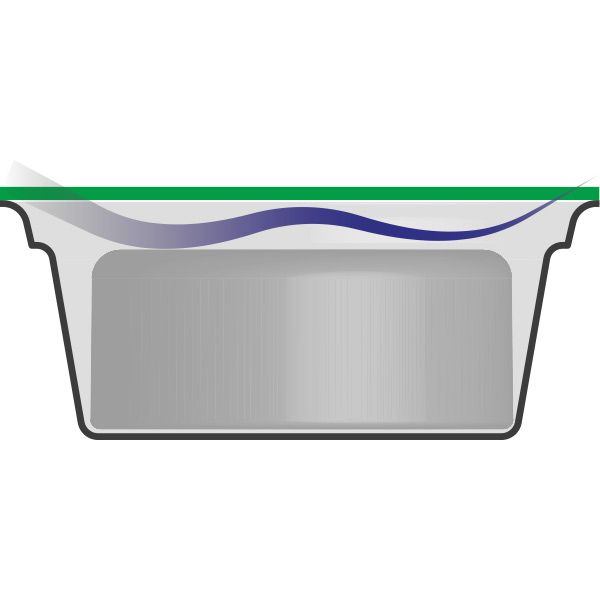

Gas Flush

Gas Flush

-

MAP/ATP

MAP/ATP

-

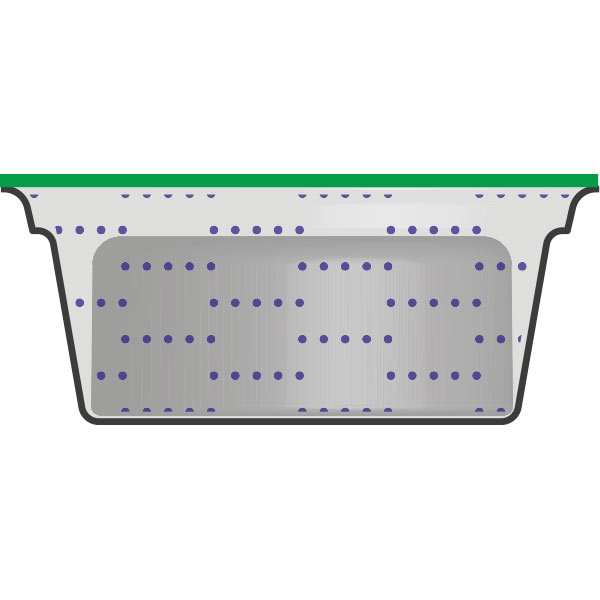

Vacuum

Vacuum

-

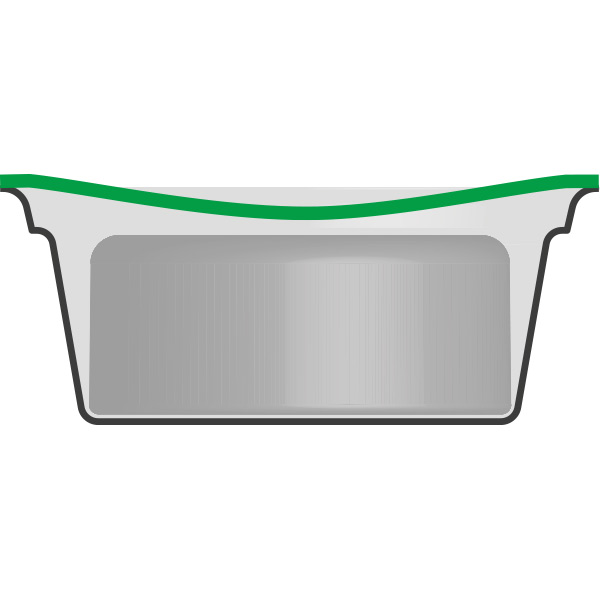

Skin

Skin

-

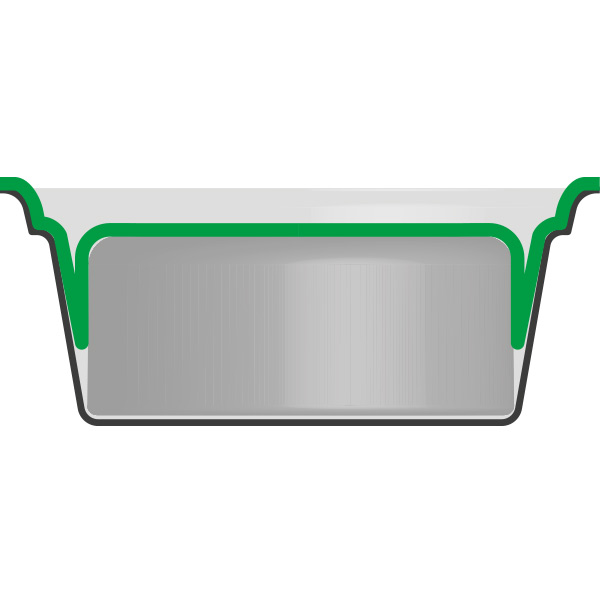

Overskin

Overskin

-

Extraskin

Extraskin

-

Extraskin on Cardboard

Extraskin on Cardboard

| Technical Data | FoodPack Speedy + | ||

| Dimensions | 287 x 106 x h 158 cm | ||

| Weight | 600 (N) / 680 (VG) Kg | ||

| Air consumption | 6 bar - 35 (N) / 40 (VG) Nlt/cycle | ||

| Sealing area | 380 x 270 x h 135 mm |

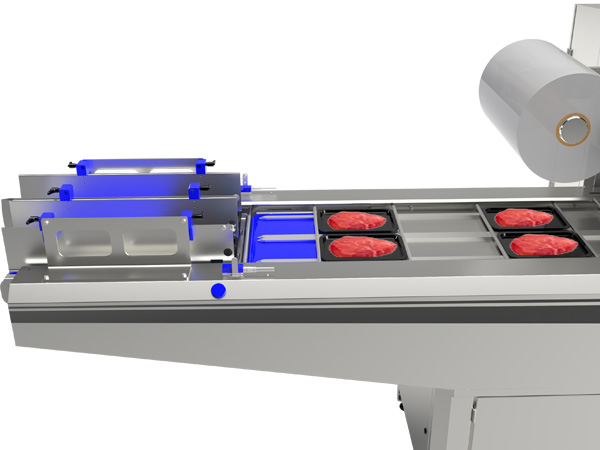

Handling via double chain with rods

In addition to the possibility of working in-line, Speedy+ counts on improved tray transport by means of a double chain with rods.

One ram pushes the tray towards the sealing area while the other positions it precisely on the plate, avoiding slippage. This synchronised and interpolated movement, like the jaws, allows high speeds to be achieved while maintaining precise container positioning without neglecting gentleness.

Touch Screen Panel

All working parameters of the machine are controlled by this unit. It stores different recipes for quick use by the operator. The panel includes access to the self-diagnostic system to process and solve any problem of the machine.

Diverger for trays

As an option, it can be equipped with the diverger model. In fact, with this accessory, you can switch from a single to a double production line easily.

Unwinding-rewinding system with automatic reels

This unit has the function of automatically placing the correct amount of heat-sealing film, unwound from a reel, in the sealing area and rewinding the scraps after the sealing-cutting operation.

TECHNOLOGIES

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| Optional: EXTRASKIN SYSTEM It allows Skin packing even at high degrees of protrusion. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |